The Future of Manufacturing How Robotic Welding Machines Are Revolutionizing the Industry

The manufacturing industry is witnessing a transformative shift driven by advancements in automation, particularly with the integration of robotic welding machines. According to a report by MarketsandMarkets, the global robotic welding market is expected to grow from USD 4.5 billion in 2020 to USD 6.8 billion by 2025, reflecting a CAGR of 8.5%. This surge can be attributed to the increasing demand for high precision and efficiency in manufacturing processes, as robotic welding machines significantly reduce human error while enhancing productivity.

Furthermore, a study by Deloitte highlights that industries leveraging automation could experience a productivity boost of between 20% to 30%, underscoring the pivotal role that robotic welding machines play in modern manufacturing. As companies embrace these innovative technologies, the future of the manufacturing landscape appears more efficient and economically viable, setting the stage for a new era of industrial capabilities.

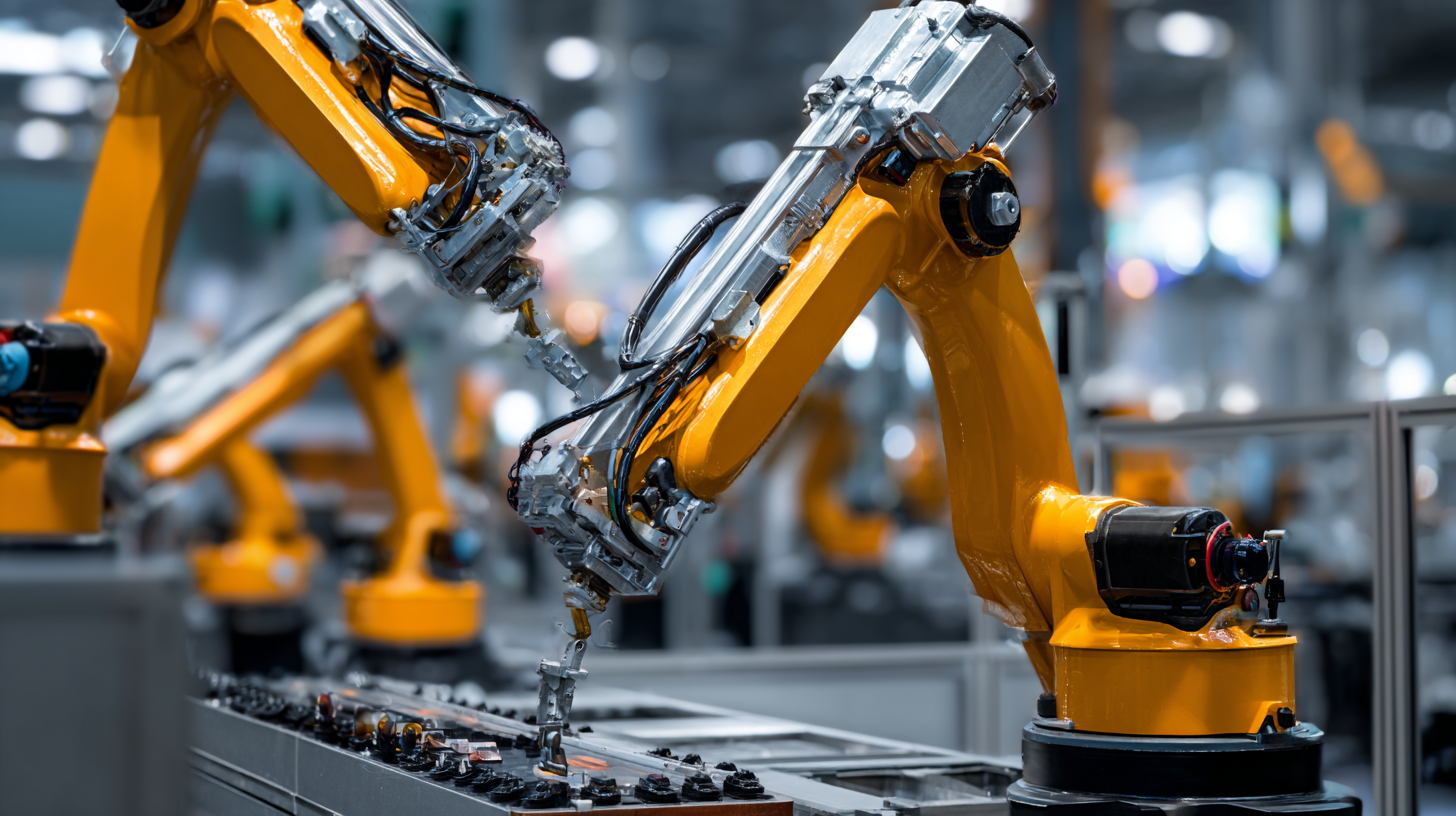

The Rise of Robotic Welding: Transforming Traditional Manufacturing Processes

Robotic welding is rapidly transforming traditional manufacturing processes, leading to increased efficiency and precision across various industries. According to a recent report by Markets and Markets, the global robotic welding market is expected to grow from $4.87 billion in 2020 to $7.85 billion by 2025, representing a compound annual growth rate (CAGR) of 10.3%. This growth is driven by the increasing demand for high-quality welds and the need for faster production cycles. Traditional manual welding can be labor-intensive and prone to human error, while robotic systems ensure consistent results, thereby enhancing product quality and minimizing waste.

Furthermore, advancements in robot technology have allowed for greater flexibility and adaptability in manufacturing processes. A study from Industry Week highlighted that companies implementing robotic welding see, on average, a 30% reduction in labor costs and a 25% improvement in production speed. With the integration of AI and machine learning, robotic welding machines can now learn from each job, optimizing welding parameters in real-time and reducing downtime caused by setup changes. As manufacturers increasingly recognize the benefits of these systems, robotic welding is poised to become a cornerstone of modern manufacturing practices.

Key Advantages of Robotic Welding Machines in Modern Industry

Robotic welding machines are paving the way for a revolution in modern manufacturing by significantly enhancing productivity and efficiency. One of the key advantages of these machines is their ability to operate with precision and consistency, reducing the likelihood of human error. As reported, automation in industries like automotive manufacturing addresses major labor costs, which can account for 65-70% of total expenses. By integrating robotic welding into the production line, manufacturers can streamline processes, decrease cycle times, and ultimately lower labor costs, leading to improved profit margins.

Moreover, the adoption of robotic welding technology contributes to safer working environments. These machines are designed to handle hazardous tasks, reducing the risk of workplace injuries associated with traditional welding methods. As the industry moves towards more intelligent systems, incorporating AI and machine vision enhances the capabilities of robotic welders, allowing them to adapt in real-time to changing conditions. This evolution not only boosts operational efficiency but also supports the workforce by taking over repetitive and physically demanding tasks, thereby enabling human workers to focus on more sophisticated and value-added activities.

The Future of Manufacturing: Key Advantages of Robotic Welding Machines in Modern Industry

| Advantage | Description | Impact on Industry |

|---|---|---|

| Increased Precision | Robotic welding machines provide higher accuracy compared to manual welding. | Reduces scrap rates and improves the quality of finished products. |

| Cost Efficiency | Lower labor costs and less material wastage lead to significant savings. | Allows companies to invest savings into other areas of production. |

| Increased Speed | Robots can operate at higher speeds without fatigue. | Shortens production cycles and increases throughput. |

| Enhanced Safety | Reducing human presence in hazardous environments minimizes risk. | Improves workplace safety and reduces liability costs. |

| Flexibility | Robotic systems can be reprogrammed for different tasks easily. | Enables adaptation to changing production needs without extensive downtime. |

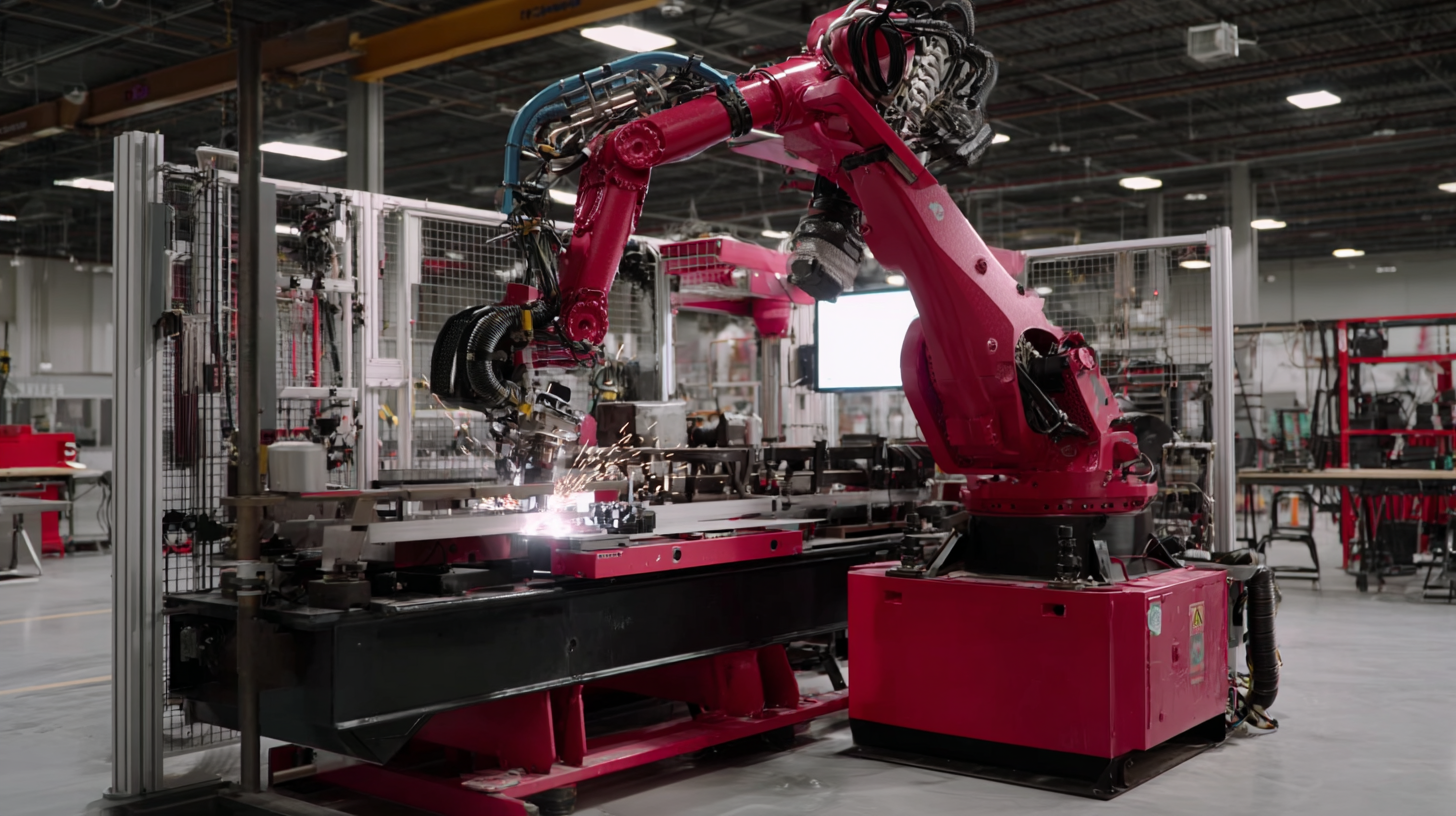

Integrating AI and Automation: The Future of Robotic Welding Technology

The integration of artificial intelligence (AI) and automation is fundamentally reshaping the landscape of robotic welding technology. As industries strive for higher efficiency and productivity, AI-driven welding robots are at the forefront of this transformation. These advanced machines are equipped with intelligent algorithms that enhance precision and adaptability, enabling them to handle complex welding tasks with greater accuracy than ever before. This technology not only reduces the potential for human error but also significantly speeds up the manufacturing process, allowing companies to meet growing demands without sacrificing quality.

In the automotive sector, the impact of AI and robotics is particularly profound. Manufacturers are leveraging these technologies to optimize assembly lines, streamline workflows, and achieve unprecedented levels of efficiency. By utilizing AI to predict maintenance needs and adjust operations dynamically, companies can minimize downtime and enhance productivity. As robotic welding becomes more sophisticated, it empowers industries to embrace a future characterized by automation, leading to improved product quality and reduced operational costs. This evolution signifies a major shift in manufacturing, where human-robot collaboration will redefine traditional production methods and drive innovation.

Cost Efficiency and Productivity Boosts Through Robotic Welding Solutions

The implementation of robotic welding solutions is significantly transforming the manufacturing landscape, primarily through enhanced cost efficiency and productivity. With the robotic welding market projected to surge, driven by advancements in welding robots and collaborative robots (cobots), industries are witnessing substantial improvements in operational processes. These automated systems enable manufacturers to perform welding tasks with a higher degree of precision, leading to reduced material waste and lower labor costs.

Furthermore, the impact of robotic welding extends beyond mere cost savings. Industries such as automotive are leveraging these technologies to boost production efficiency, streamline workflows, and reduce lead times. As manufacturers increasingly adopt intelligent robotics solutions, they'll not only optimize their production capabilities but also position themselves favorably in the competitive global market. With a projected market size of over USD 291.1 billion by 2035, the future of manufacturing is poised for revolutionary changes brought about by rapid advancements in robotic welding technology.

The Future of Manufacturing: Impact of Robotic Welding Machines

Skills for Tomorrow: Preparing the Workforce for Robotic Integration in Manufacturing

As robotic welding machines continue to transform the manufacturing sector, the need for a workforce that is skilled in operating and integrating these advanced technologies is becoming increasingly crucial. According to a report by the International Federation of Robotics (IFR), the global stock of industrial robots is expected to reach 4 million units by 2025, highlighting a growing reliance on automation in manufacturing processes. This shift toward automation not only enhances productivity but also requires workers to adapt to new roles that involve overseeing and maintaining robotic systems.

To prepare the workforce for this inevitable transition, educational institutions and training programs must evolve in tandem with technological advancements. A study from the McKinsey Global Institute predicts that by 2030, as many as 375 million workers may need to change occupational categories due to the increasing integration of automation and artificial intelligence. Emphasizing STEM (science, technology, engineering, and mathematics) education, vocational training, and reskilling initiatives will be essential in equipping the workforce with the necessary skills to thrive in a robotic-integrated manufacturing landscape. As the industry moves forward, fostering a culture of continuous learning and adaptability will be critical for both workers and companies alike.

Related Posts

-

Exploring the Future of Work with Robotic Automation Solutions

-

Maximizing Efficiency in Manufacturing with Advanced Robotic Welding Systems and Their Impact on Production Rates

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations

-

Revolutionizing Efficiency: How Robotic Process Automation Solutions Transform Modern Workflows