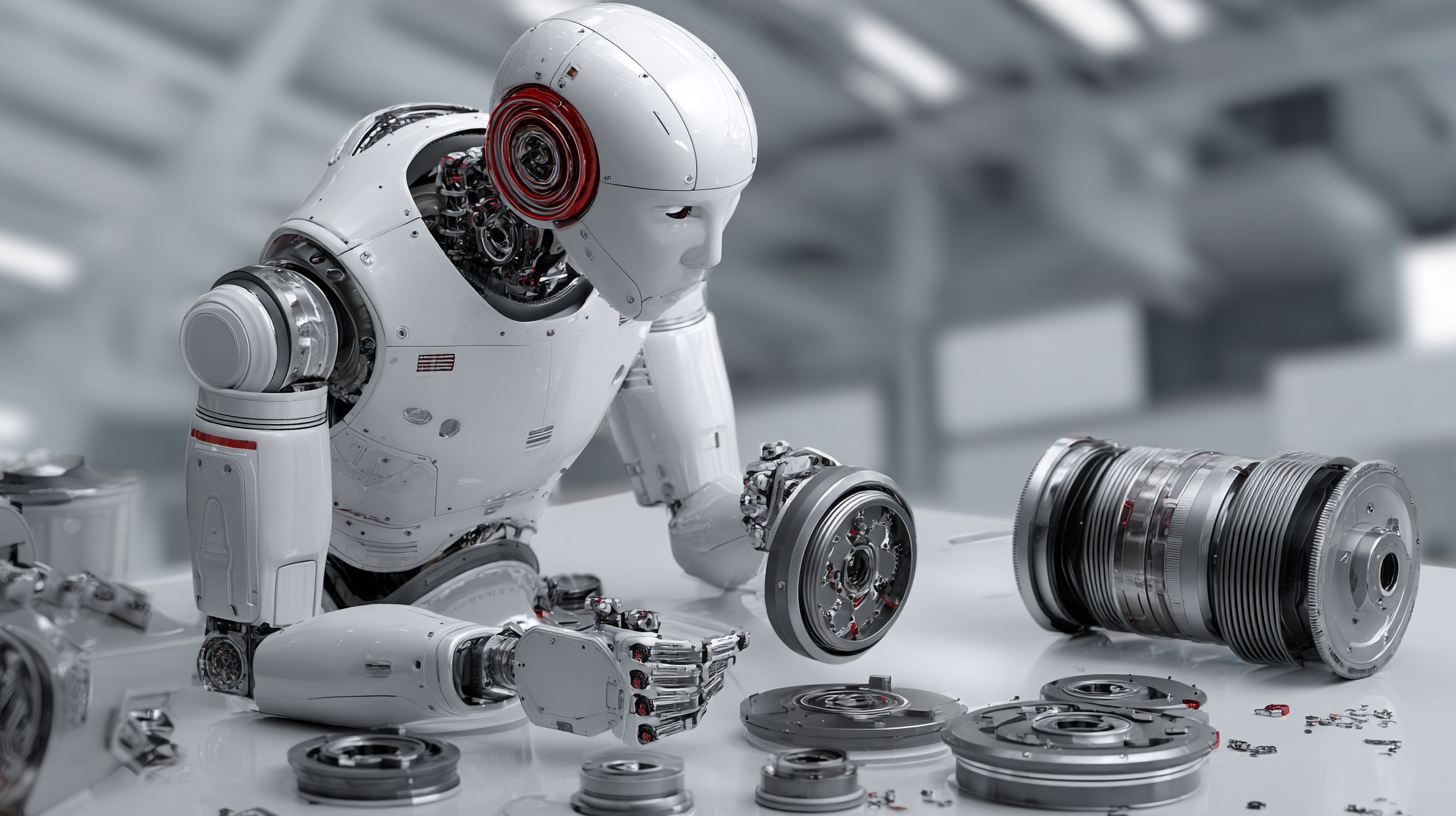

What is Robot Parts? A Comprehensive Guide to Components and Their Uses in Robotics

In the ever-evolving landscape of technology, the field of robotics has emerged as a pivotal area of innovation, driven by increasingly sophisticated robot parts. As per a report by the International Federation of Robotics (IFR), the global industrial robot market is projected to exceed $70 billion by 2025, highlighting the crucial role that various components play in the efficiency and functionality of robotic systems. Understanding the intricacies of robot parts is essential for engineers and developers aiming to design advanced automation solutions that can outperform human capabilities in precision and productivity.

At the core of robotics lies a diverse range of components, each serving distinct purposes that contribute to the overall operation of a robot. From sensors that gather environmental data to actuators that initiate movement, the integration of these parts is vital for creating systems that can interact seamlessly with their surroundings. The burgeoning demand for intelligent robots in sectors such as manufacturing, healthcare, and logistics underscores the necessity for a comprehensive understanding of robot parts, their functionalities, and their applications in creating smarter, more efficient robotic solutions. As we delve further into the realm of robotics, a thorough exploration of these components will provide the foundation for future advancements and innovations in the industry.

Understanding the Importance of Robot Parts in Modern Robotics Applications

The significance of robot parts in modern robotics applications cannot be overstated. Each component, from sensors to actuators, plays a critical role in the functionality and efficiency of robotic systems. For instance, sensors enable robots to perceive their environment, facilitating tasks ranging from simple object recognition to complex navigation in dynamic settings. This ability to gather and process data is essential for robots to make informed decisions, respond to changes, and interact safely with humans and other machines.

The significance of robot parts in modern robotics applications cannot be overstated. Each component, from sensors to actuators, plays a critical role in the functionality and efficiency of robotic systems. For instance, sensors enable robots to perceive their environment, facilitating tasks ranging from simple object recognition to complex navigation in dynamic settings. This ability to gather and process data is essential for robots to make informed decisions, respond to changes, and interact safely with humans and other machines.

Moreover, actuators are fundamental in translating the robot's computational directives into physical actions. They provide the necessary movement, whether it’s through motors that drive wheels or servos that control robotic arms. The integration of various robot parts enhances versatility, allowing robots to perform an array of functions across industries such as manufacturing, healthcare, and logistics. As robotics technology continues to advance, the optimization and innovation of these components will be pivotal in unlocking new potentials and applications in the ever-evolving landscape of automation.

Key Components of Robots: Motors, Sensors, and Control Systems

In the rapidly evolving field of robotics, key components such as motors, sensors, and control systems play a pivotal role in determining a robot's functionality and efficiency. According to a report by MarketsandMarkets, the global robotics market is projected to reach $237 billion by 2024, driven largely by advancements in these core components. Motors, particularly servo and stepper types, provide precise movement control crucial for applications ranging from manufacturing to medical devices, indicating their significance in the construction of efficient robotic systems.

Sensors also stand at the forefront of robotic technology by enabling machines to interact with their environments. A study from Research and Markets highlights that the sensor market in robotics is expected to grow from $1.2 billion in 2021 to nearly $3 billion by 2026, illustrating the increasing reliance on sensory feedback for tasks such as navigation and obstacle avoidance. Control systems integrate the information received from these sensors and the commands from software algorithms, ensuring seamless operation. The synergy among these components not only enhances the operational capabilities of robots but also fosters innovations in fields like automation and artificial intelligence, further contributing to the growth of the robotics sector.

Key Components of Robots: Motors, Sensors, and Control Systems

How Actuators Drive Robot Motion: Types and Applications

Actuators are crucial components in robotics, functioning as the driving force behind the motion of robots. These devices convert energy into physical motion, playing a pivotal role in various robotic applications. According to a recent market report by Research and Markets, the global actuator market for robotics is projected to reach $17.6 billion by 2025, showcasing the growing demand for efficient motion solutions in automation. There are several types of actuators used in robotics, including electric, hydraulic, and pneumatic actuators, each offering distinct benefits tailored to specific applications.

Electric actuators are widely favored for their precision and ease of control, making them ideal for tasks requiring quick responses and accuracy. Hydraulic actuators, on the other hand, deliver immense power, making them suitable for heavy-duty applications such as industrial robots. Pneumatic actuators utilize compressed air to facilitate fast movements, often used in assembly line settings. For those looking to optimize their robotic systems, understanding the different actuator types is essential for selecting the most appropriate one for your needs.

**Tips:** When choosing an actuator, consider the specific requirements of your application, such as load capacity and speed. Additionally, ensure to evaluate the energy efficiency of the actuator, as it can significantly impact operational costs over time. Regular maintenance is crucial for prolonging the lifespan of actuators—make it a part of your robotic system's routine to avoid unexpected downtimes.

The Role of Power Supply Systems in Robotic Efficiency

Power supply systems play a critical role in enhancing the efficiency of robotic applications across various industries. As robotics increasingly integrates into warehouse settings, optimizing energy consumption becomes paramount. For instance, advancements in robotic process automation (RPA) have enabled smarter demand-side management in microgrids, allowing for more efficient energy use in robotic operations. This not only boosts overall productivity but also helps companies mitigate operational costs, ensuring they can meet rising consumer demands.

Power supply systems play a critical role in enhancing the efficiency of robotic applications across various industries. As robotics increasingly integrates into warehouse settings, optimizing energy consumption becomes paramount. For instance, advancements in robotic process automation (RPA) have enabled smarter demand-side management in microgrids, allowing for more efficient energy use in robotic operations. This not only boosts overall productivity but also helps companies mitigate operational costs, ensuring they can meet rising consumer demands.

In this context, innovations in power supply technologies are transforming how robots operate. With techniques such as pairing rooftop solar energy with warehouse robotics, businesses can significantly improve their energy sustainability while leveraging high-tech solutions. Moreover, inspection robots are enhancing power supply safety by conducting essential evaluations in critical infrastructure, demonstrating how energy management systems are intertwined with efficient robotic functionality. As these technologies continue to evolve, the synergy between power supply systems and robotic efficiency will likely define the future of automation in diverse sectors.

Emerging Technologies in Robotics: 3D Printing and Material Innovation

3D printing and material innovation have emerged as game changers in the field of robotics, eliminating many of the traditional barriers to rapid prototyping and custom manufacturing. According to a report by SmarTech Analysis, the global market for 3D printing in robotics is projected to reach over $4 billion by 2026, reflecting the growing demand for cost-effective and streamlined production methods. This technology allows engineers to create complex geometries that were previously impossible with conventional manufacturing techniques, enabling the development of sophisticated robotic components tailored to specific functions.

As materials science continues to evolve, advancements such as lightweight composites, biocompatible materials, and smart materials are enhancing the performance and versatility of robotic systems. A study from the International Federation of Robotics highlights that integrating these innovative materials can improve efficiency and longevity in applications ranging from industrial automation to healthcare robotics.

Tips: When exploring components for robotic applications, consider leveraging 3D printing to prototype designs rapidly. This approach not only reduces lead times but also allows for easy iterations, saving both time and resources. Additionally, staying informed about the latest material innovations can significantly impact the overall performance of robotics systems, giving you a competitive edge in design and functionality.

What is Robot Parts? A Comprehensive Guide to Components and Their Uses in Robotics - Emerging Technologies in Robotics: 3D Printing and Material Innovation

| Component | Description | Use Case | Material Innovation |

|---|---|---|---|

| Actuators | Devices that convert energy into motion. | Used in robotic arms for precise movements. | Advanced materials for better energy efficiency. |

| Sensors | Instruments that detect and measure physical properties. | Navigation and obstacle detection in autonomous robots. | 3D printed sensor housings for lightweight designs. |

| Controllers | Systems that manage the operation of robots. | Used for real-time processing of inputs and outputs. | New microcontroller materials for reduced heat and increased performance. |

| Power Supply | Provides electrical energy to the robot. | Batteries and power sources for mobile robots. | Innovative battery chemistries for longer life. |

| Chassis | The base structure of the robot that supports components. | Provides stability and a framework for building robots. | 3D printed chassis for customization and weight reduction. |

Related Posts

-

The Future of Manufacturing How Robotic Welding Machines Are Revolutionizing the Industry

-

Exploring the Future of Work with Robotic Automation Solutions

-

Revolutionizing Efficiency: How Robotic Process Automation Solutions Transform Modern Workflows

-

Unlocking Efficiency: How Robotic Automation Solutions are Transforming Everyday Business Operations

-

The Future of Manufacturing Embracing Robotic Welding Systems and Their Impact on Industry

-

Revolutionizing Manufacturing: The Impact of Automated Welding Cells on Production Efficiency